CNC Machine Tool Holder Bt30 Bt50 Bt40

Description

Basic Info.

| Model NO. | Bt40-Lbk4 |

| Size | Middle |

| Customized | Customized |

| Type | Cutting Tool |

| Material | Stainless Steel |

| Certification | ISO 9001:2000 |

| Brand | Ounuowei |

| Keyword | Cat50 Tool Holder |

| Model | Er11 Er16 Er25 Er32 Er40 |

| Name | Cat50 Tool Holder |

| Transport Package | Plastic Box |

| Specification | cat40 |

| Trademark | ounuowei |

| Origin | Shandong, China |

| HS Code | 8466100000 |

| Production Capacity | 5000PCS/Month |

Packaging & Delivery

Package Size 58.00cm * 43.00cm * 36.00cm Package Gross Weight 15.000kgProduct Description

Product Description

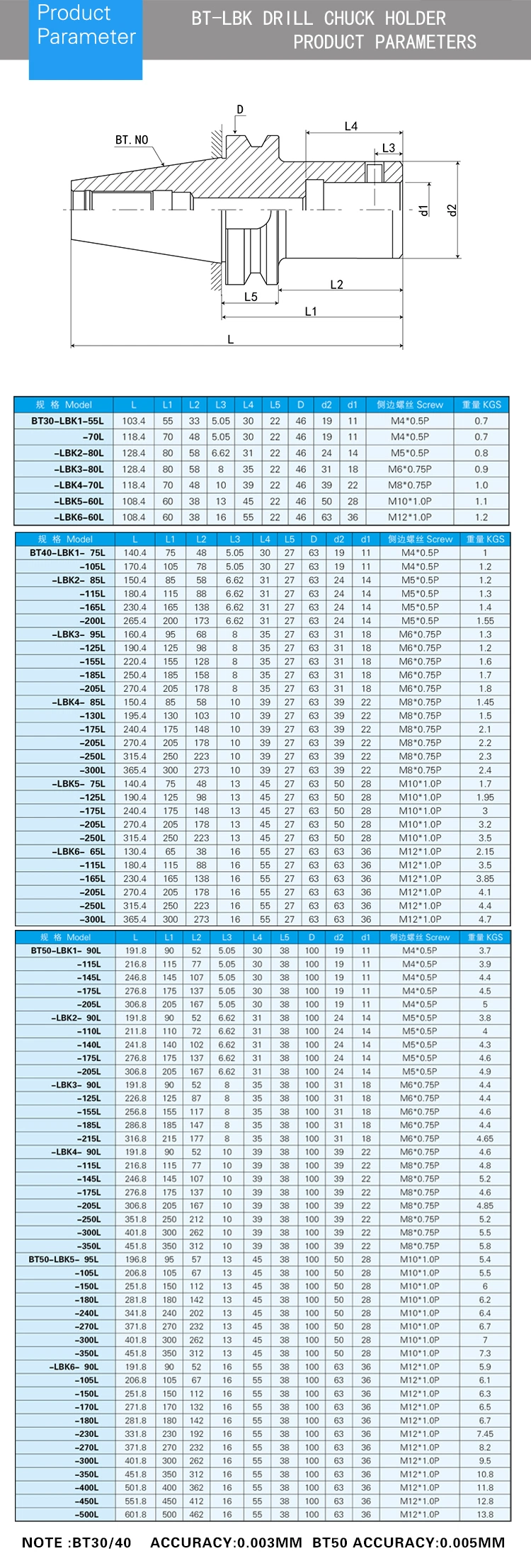

| Name | Machine Tools Bt40-Lbk4 Shanks Bt40 Boring Head Shank Lbk Type Boring Tool Holder for CNC Machine |

| Material | Steel |

| Model | BT30 BT40 BT50 lbk1 lbk2 lbk3 lbk4 lbk5 |

| Brand | Ounuowei |

| Customization | Support |

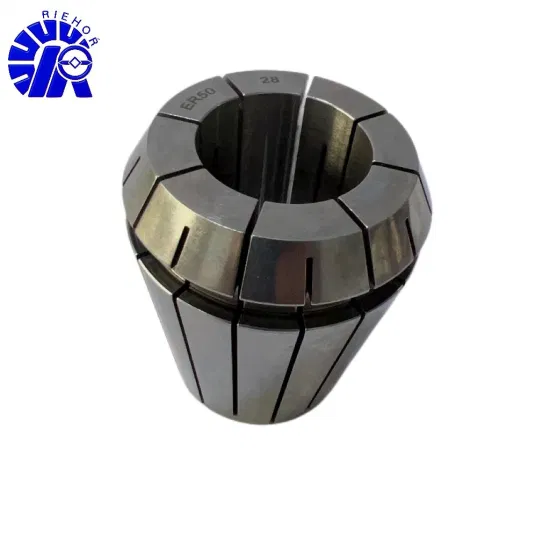

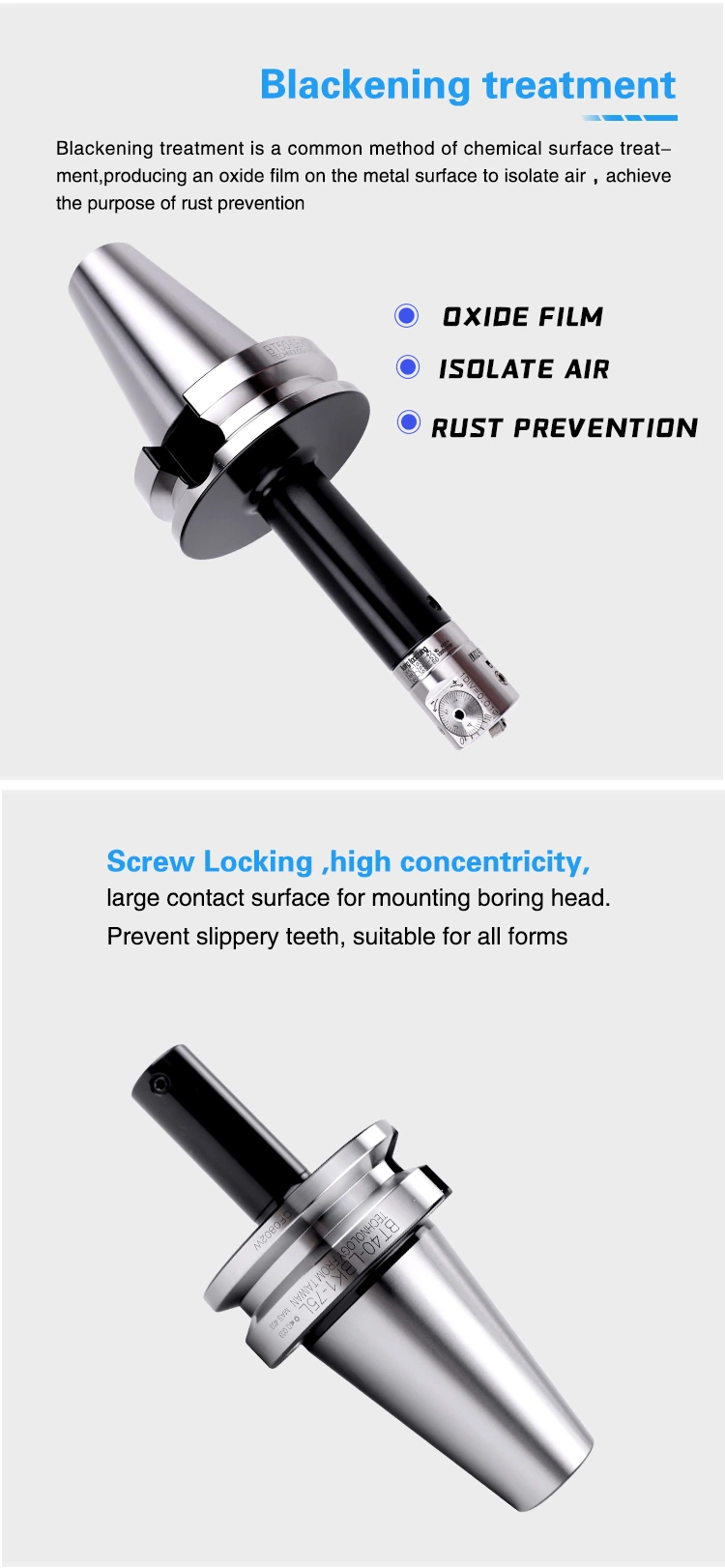

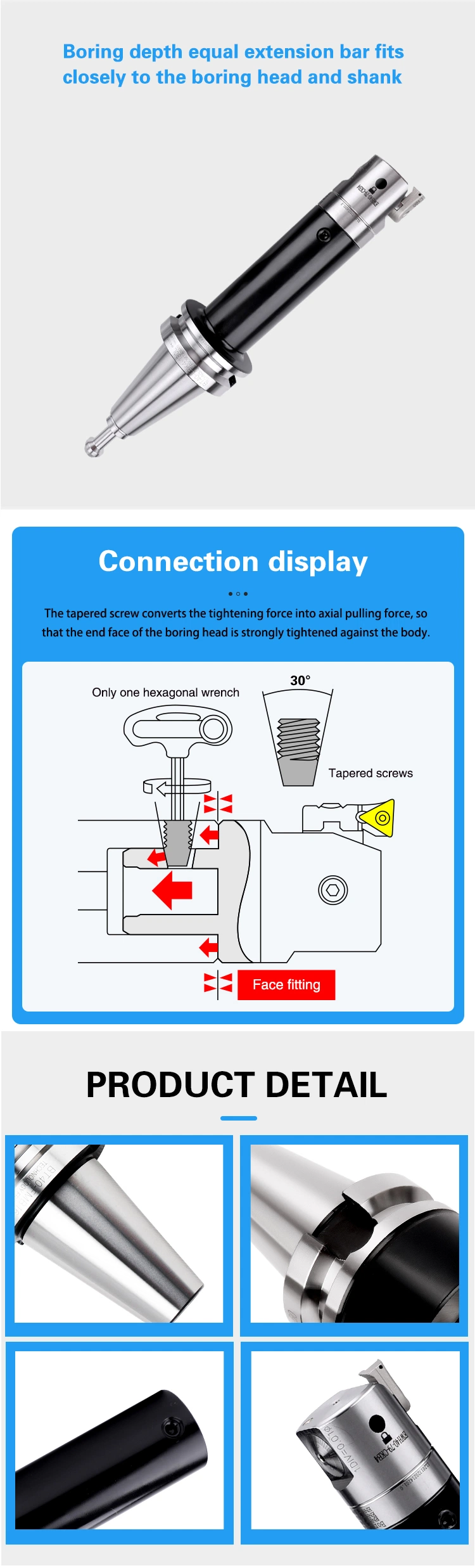

BT boring head shank is a tool holder used in boring operations. The shank is the cylindrical portion that connects the tool holder to the machine spindle. It is typically made of high-grade steel and has a precision finish to ensure accurate and stable clamping of the boring head.

The BT boring head shank is compatible with BT tooling systems, which are widely used in CNC machining centers. The shank has a tapered connection that provides a secure grip and prevents the tool from slipping during operation. It also has a retention knob that locks the boring head in place, ensuring repeatable positioning and accurate machining.

The length and diameter of the shank can vary depending on the application and machine requirements. The shank can be short or long, and it can have a straight or angled design. Moreover, it can have different types of flanges, such as V-flange or HSK, to fit different types of machining centers.

In summary, the BT boring head shank is a critical component in boring operations, providing a secure and accurate connection between the tool holder and the machine spindle. Its precision design and construction help to ensure high-quality machining results.

Company Profile

Shandong Ounuowei CNC Tool Co., Ltd, founded in 2014,We mainly produces various of CNC tool systems such as CNC tool holders, live centers, spring collets, boring heads, milling chucks,drill chucks, pull studs and other machine accessories which are sold to Australia, South Africa, United States,Russia, Europe, Middle Asia, South America and Southeast Asia, and more than fifty countries and regions.Welcome to visit our factory.

Our Services:1. Guarantee quality which mainly embodied in real accuracy.2. Huge production capacity to ensure in time delivery3. Manufacture that can accept OEM service.4. Professional sales team and engineers.5. Sufficient experience in domestic and international sales6. Prompt reply which response in 15 minutes7. Never stop in innovating and improving

Our mission:making CNC machining more efficientmanufacturing wonderful Chinese CNC toolsOur sense of value:Customers is the first, staffs is the second, shareholders is the third;Market oriented and customer centric;Charity begins at home,but should not end there.Treat suppliers as brothers and seeking mutual benefit;Stick to innovation and sustainable development;Teamwork and share duties and benefits.

Equipment

The company has more than 150 sets of production equipment and testing equipment, such as Japanese Mazak CNC lathes, Mazak five-axis machining centres, Swiss Klingberg CNC compound grinding machines, Japanese Mitutoyo three coordinates, cylindricity meters, contouring meters and German Daibo toolholder inspection tools.

Certifications

Our company has passed ISO9001 quality system certification,SGS Certification ,Tuv certification

FAQ

1.Are you a factory or trading company ?

We are a manufacturer ,and we also have our own trading company ,we have professional R&D team .sale team .We can provide you the best quality goods and the perfect service .2.Could you provide non standard products ? Yes we can.we can also make and supply the goods as delivered samples or drawing .3.What is the advantage about your company ? Our company has professional team and professional production line .4.Why should I choose your products ? Our products are high quality and good price5.Any other good service your company can provide ? Yes ,we can provide good after-sale and fast delivery6.How can we guarantee quality ? We follow our QC manual and inspect all data of our products 100%Our Contact